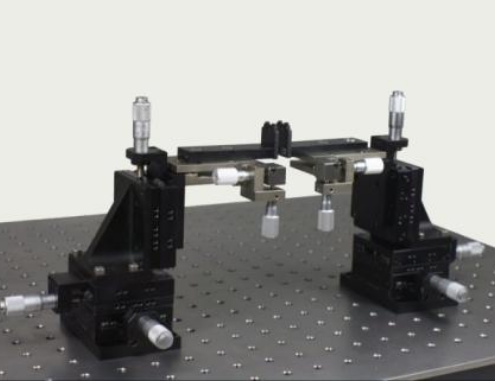

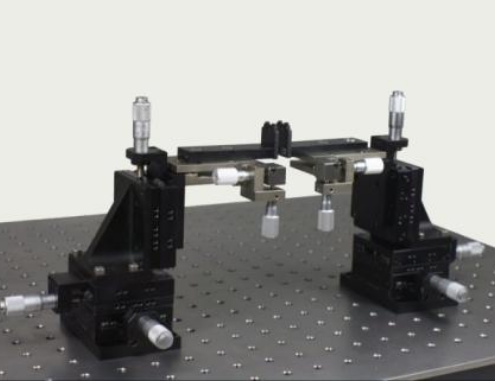

The optical adjusting frame of the Futansi angle table includes a mirror frame, a connecting block and a driving component fixed on both sides of the connecting block. The driving component includes a stepping motor and a micro planetary gear reducer connected with the stepping motor, in which the connecting block is a cavity structure, and an elastic coupling arranged in the cavity structure of the connecting block and connected with the output shaft of the micro planetary gear reducer. It also includes a precision screw connected with the output end of the elastic coupling, the end of which falls on the upper surface of the frame, and a spring connecting the connecting block at one end and the frame at the other end. The end of the precision screw is provided with a conical groove A, and a cemented carbide hemisphere fixed in the conical groove A through line contact. The bottom tribe of the cemented carbide hemisphere is in the mirror. The upper surface of the frame. In the present embodiment, the precision screw is connected with the telescopic coupling, so the frame can be fine-tuned by moving the precision screw up and down under the action of the motor.

Examples of corner table applications:

1. Prism positioning and mounting of LCD projector. Applied to optical fiber adjustment. Optical fiber coupling.

2. Optical fiber positioning, optical communication system products and testing equipment.

3. Semiconductor related production equipment and inspection and evaluation equipment, tester, inspection device, processing machine, precision machinery equipment, led processing equipment, laser cavity position adjustment.

Futansi(Shanghai) Co., Ltd. produces: high-precision displacement table, fine-tuning table, angle table, six-dimensional adjusting frame, cross-rail adjusting frame, multi-dimensional displacement table, cross-rail sliding table, optical adjusting frame, manual displacement table, etc. Welcome to inquire.