Manual adjusting frame is a moving tool mainly composed of manual displacement. Mainly used in equipment moving positioning, parts processing, thread processing, guide positioning and other mechanical equipment. Manual adjusting frame can be divided into different levels according to its characteristics, and adjusting frame can be divided into one-dimensional, two-dimensional, three-dimensional, four-dimensional, five-dimensional, six-dimensional and so on. This is just a simple single adjusting frame. If it is processed by different sophisticated instruments, it can be combined into adjusting frames of different dimensions and shapes according to the characteristics of different adjusting frames. The adjusting frame mainly determines the displacement and the travel accuracy according to the differential head, guide rail and gear.

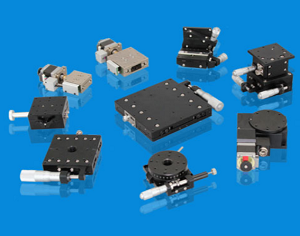

Linear slide, arc slide, rotary fine-tuning frame, rotary slide, electric adjusting frame precision fine-tuning platform, precision guide rail moving platform, mechanical slide, cross slide, linear slide, CNC slide.

2. Accuracy: Accuracy of customer requirements is achieved at a reasonable price. Accuracy is generally between 5um and 0.5um. Customers can choose products according to different needs. Accuracy of electric products can reach 0.05um pulse (MS1/20*), which can fully meet the needs of industrial students in automatic fine-tuning.

3. Diversification: In order to meet the different needs of different customers, we adjust the platform's journey and the size of the mesa. The mesa size has a series of larger products, such as 25*25, 40*40, 60*60, 80*80, 120*120. The journey is 6.4mm-350mm for different products, and the single axis (X Y Z axis straight platform, 120*120, etc.). Rotary platform and arc mobile platform can be combined into two-dimensional, three-dimensional, four-dimensional, five-dimensional and six-dimensional multi-dimensional platform to meet the adjustment of different directions and angles.